Contents:

Some of us don’t complete most of the projects we undertake until the very last minute. Sometimes, we struggle with what to call them before they become finished products. Many business dictionaries state that there is no difference between the terms work in process and work in progress, so it is possible to interchange the terms. However, there is a difference based on the common usage of the terms process and progress.

County Council Approves Purchase of 2 Dodge Durangos for Sheriff … – WTCA

County Council Approves Purchase of 2 Dodge Durangos for Sheriff ….

Posted: Fri, 31 Mar 2023 07:00:00 GMT [source]

The accountant can then compare the real-world data with the financial metrics to make sure everything checks out. Some companies may attempt to complete all work in process items for simpler, cleaner financial statements. Though not required, the goal is to eliminate any pending products to only report completed goods. When these goods are completed, they are often transferred to inventory to later to be treated as a cost of good sold when purchased by a customer. Since WIP inventory is an inventory asset, neglecting to include it on your business’ balance sheet can cause your total inventory to be undervalued.

Work in Process Inventory – What Is WIP and How To Calculate it?

Whenever any wood is taken and used to build the chair the cost of that wood is a debit to the work-in-process inventory and a credit to the raw materials inventory. Whenever direct labor is incurred there is a debit to the work-in-process inventory and a credit to the wages payable account. For each direct labor hour incurred, the firm must debit work-in-process and credit a manufacturing overhead account.

In this scenario, the mixed clay and the unglazed mugs are no longer part of WIP. That’s because once you’ve finish mixing the clay, you report the clay as completed on its own production order. The beginning work in progress inventory is the ending balance from the prior accounting period, i.e. the closing carrying balance is carried forward as the beginning balance for the next period. Once the product is marked as a finished good and is subsequently sold, the appropriate amount is removed inventory balance on the balance sheet.

PRODUCTS

Manufacturing Work In Process lets manufactures track work orders through the production process, from gathering materials, through shop floor assembly, to stocking finished goods. Suppose a company commits all its resources to five projects, and it would take about a month to complete each of them. Focusing on all of them at the same time is unlikely to get them completed in the first month.

forensic accounting defined may also abbreviate to work-in-progress inventory but the two phrases are generally used intermittently in manufacturing and accounting. To end this article, let’s take a look at why effectively managing and keeping WIP inventory as slim as possible is also good from a production and inventory management viewpoint. Inaccuracies in accounting can lead to a host of issues and unwanted attention. Overestimating it, on the other hand, can be equally detrimental as it creates unnecessarily high tax responsibilities. To differentiate between different financial periods, the WIP inventory value for the current period is sometimes also called the ending work-in-process inventory.

- This excludes the value of raw materials held up in inventory for sale and finished goods inventory held for the anticipation of future sales.

- Flexible management often focuses on multitasking, among other things.

- The WIP figure also excludes the value of finished products being held as inventory in anticipation of future sales.

The vendor’s latest industry-specific platform — its sixth — is aimed at manufacturers and comes with best practices, a set of … When it came time to move from SAP ECC to S/4HANA Cloud, Jabil chose to lift-and-shift systems in stages. We grow your business by getting you closer to your customers with guaranteed 2-day delivery.

How to Calculate Work-in-Process Inventory

One that describes the physical state of the inventory, and another that describes an account used to track the value of work-in-process. Longer WIP Stage → The longer the items remain in the work in progress stage, the less efficient that company may be – all else being equal. Generally, most companies strive to reduce the amount of time that inventory spends at the work in progress stage. Flexible management often focuses on multitasking, among other things.

The costs included in the work-in-process inventory account are direct materials, direct labor, and manufacturing overhead. WIP inventory accounting involves keeping track of the costs of unfinished goods as they move through the production process. WIP is considered a current asset in the company’s balance sheet and represents the total value of all materials, labor, and overhead of the unfinished products. As the name implies, WIP inventory accounting involves keeping track of the costs of unfinished goods as they move through the production process.

Work-in-process inventory is materials that have been partially completed through the production process. These items are typically located in the production area, though they could also be held to one side in a buffer storage area. The cost of work-in-process typically includes all of the raw material cost related to the final product, since raw materials are usually added at the beginning of the conversion process. Also, a portion of the direct labor cost and factory overhead will also be assigned to work-in-process; more of these costs will be added as part of the remaining manufacturing process.

Army men’s basketball new coach Kevin Kuwik: What to know – Times Herald-Record

Army men’s basketball new coach Kevin Kuwik: What to know.

Posted: Fri, 14 Apr 2023 12:15:08 GMT [source]

This is correct, but some people make a distinction between the two. Work in process may refer specifically to products that are completed in a short time. Work in progress is then taken to mean production that takes considerable time, such as a construction project. The limitations of having a Work-in-Process inventory include increased holding costs, the potential for obsolescence or spoilage, and increased risk of production delays or bottlenecks.

Final Thoughts on ‘Work in Progress’ and ‘Work in Process’

All of the following terms are under the umbrellas of manufacturing inventory. Whereas, Work in progress is a term used mainly in the construction business when a certain building is being constructed. Eric Sottile has a bacholors degree in accounting from the University of Kentucky and a bachelors degree in finance from the University of Kentucky. Eric works for a public accounting firm and has passed his CPA exams with an average score of 94. On transactions using WIP, you must identify a WIP location for line items. The WIP line location must match on all work order issue, work order completion, and work order close transactions.

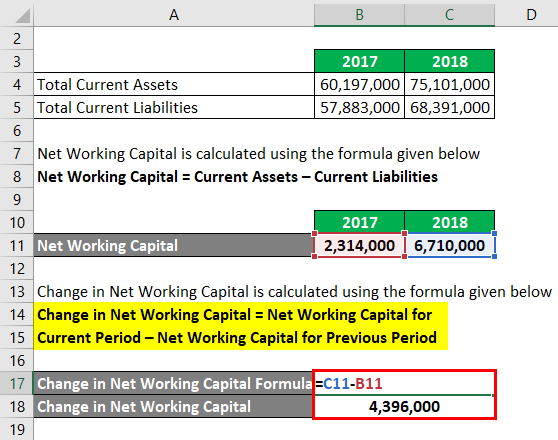

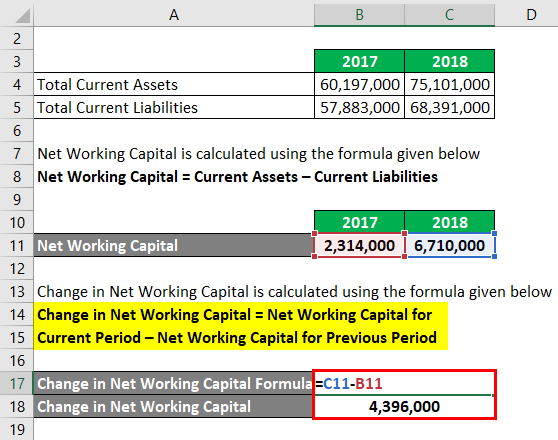

COGM can be determined by adding the total manufacturing costs to the beginning WIP inventory, followed by subtracting the ending WIP inventory. COGM is defined as the total costs incurred while creating a finished product, and in order to estimate the value of a company’s end-of-period WIP, the finished COGM is a necessary input. Work In Progress → The process of turning the raw materials into finished goods has begun, however, the item is not yet ready to be sold. There are things it doesn’t consider, like waste, spoilage, downtime, scrap, and MRO inventory.

The inputted value of https://1investing.in/ inventory is often not the final amount, as other costs for packaging, storage, and transportation are also added in later steps. It is essential for any manufacturing company to know the exact amount of inventory they hold whether it is in terms of raw materials or work in process inventory. Inventory management helps in counting and maintaining all kinds of inventory. The accurate number of inventory by regularly counting the stock will give the manufacturer a fair idea of how much needs to be produced and also help in forecasting the production as per the demand. Work-in-process is considered inventory and is included as a current asset on the balance sheet.

Taking time to classify WIP inventory in a warehouse waiting to be assembled might seem tedious, but it’s crucial for monitoring and improving your supply chain and inventory control. Learn how to classify work in process inventory to increase the efficiency of your inventory management operations. I just got the works-in-process report from the accounting department. The numbers look pretty good, but we might need to speed up production to meet our quota. In certain industries, ‘work in process’ means unfinished goods in a manufacturing context.